Fatalities Involving Roadway Maintenance Machine Strikes Published: Nov 30 2015 1:01PM

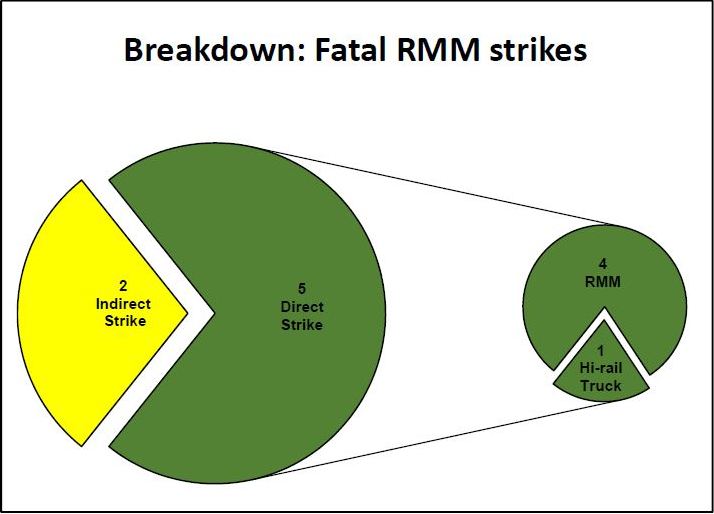

Dedication: The FAMES Committee dedicates its efforts to all roadway workers who have lost their lives in the performance of duty and to the families, loved ones, and coworkers they have left behind. Mission Statement: The Mission of the Fatality Analysis of Maintenance-of-way Employees and Signalmen (FAMES) Committee is to analyze all fatalities and selected related incidents in order to make recommendations to reduce the risk of future occurrences and eliminate fatalities to roadway workers. Since the implementation of the Roadway Worker Protection (RWP) regulations in 1997, there have been too many RWP accidents in which Roadway Workers were killed or injured. To date, FAMES has analyzed 41 Roadway Worker fatalities; 7 involved strikes by Roadway Maintenance Machines (RMMs), which includes hi-rail vehicles.

Findings:

o In 2 of the fatalities, the roadway worker on the ground was struck by an RMM that was impacted by another RMM (i.e., indirect strike).

o In 4 of the fatalities, the roadway worker was struck by an RMM (i.e., direct strike).

o In 3 of these 4 fatalities, the RMM was making a reverse move.

o In 1 of the fatalities, the roadway worker was struck by a hi-rail truck (i.e., direct strike).

Recommendations:

Recommendations:

- Job briefings should include information regarding hazards of the work area, especially the zone to the front and rear of RMMs.

o RMM operators and Roadway Workers must establish a clear means of communication when working in close proximity.

o RMM operators must clearly communicate signals for slowing, stopping, and changing direction.

o RMM operators should communicate whenever an RMM is stopped for repairs or supplies and consider using warning devices, such as safety cones or flags, or flagmen.

- Roadway workers on the ground must communicate with and receive a response from the RMM operator before entering the work area to the front or rear of an RMM.

o Employees should be mindful that impact collisions between RMMs can result in one of the RMMs being propelled into roadway workers on the ground.

- Identify, discuss, and mitigate the risks associated with environmental conditions (e.g., wet, icy, oily/greasy rails) which can affect the stopping distance of RMMs.

- Track grade, speed, and sight distance, as well as the number and weight of push carts or coupled equipment, must be considered in determining stopping distances.

- Maintain a safe distance between RMMs when traveling or working.

The FAMES Committee consists of safety representatives from a cross section of rail labor, railroad management, and federal regulators. FAMES is a continuous improvement process that relies on the candid sharing of available data and the views of its participants. To enable the process, FAMES explicitly refrains from making any findings regarding whether any past or present practice or protocol satisfies any legal duty or standard of care.

The views, opinions, and recommendations contained in this report are those of the FAMES Committee and do not necessarily represent the views, opinions, or recommendations of any specific railroad, labor organization, or governmental agency.